Ultrasonic stripping machine that is compact and automated

Mineral insulated cable stripping machine specially designed to obtain the bare terminals using computer-driven processing technologies to achieve the best quality and efficiency with simplicity.

This machine simultaneously uses both ultrasounds that break down the hardened powder, and another modulated vibration that favors the release of the powder.

The setup is simple with finely adjustable Ultrasonic power and also the vibrating force can be adjusted and eventually Modulated activating a switch.

Great OLED graphical display that report setup values and show current status.

The cables must be prepared by cutting the metal sheath almost to the insulation but not completely so as not to push the material inwards: see our Ringing machine for a precise incision.

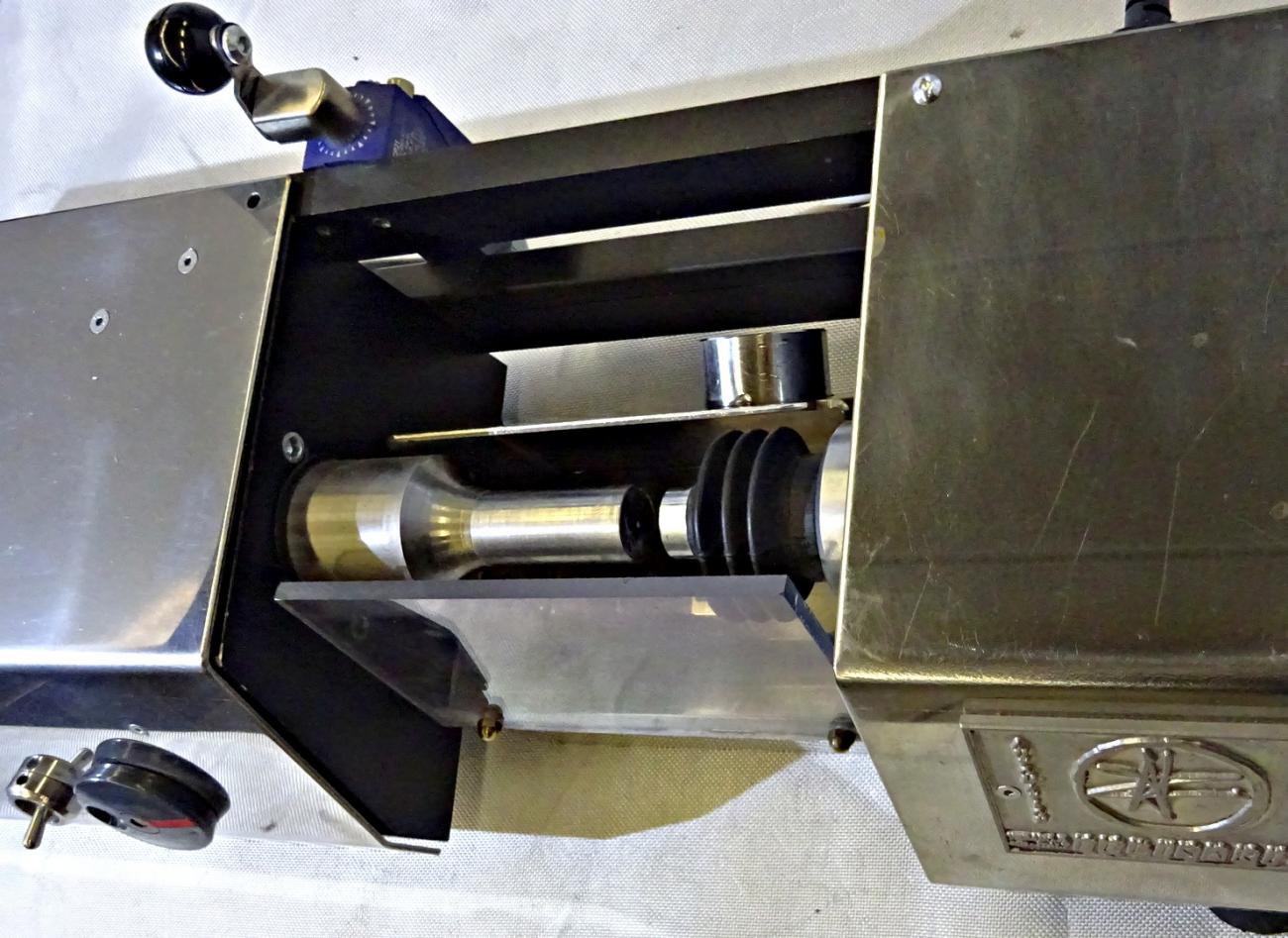

- Place the cable sheath to remove between the ultrasonic transducer and magnetically excited cylindrical hammer.

- When the activation switch is pressed, the cable is immediately "clamped" between the ultrasonic transducer and the vibrating hammer: in a few seconds, the ultrasounds finely disaggregate the compacted powder and at the same time another type of vibration favors the release of dust from cable head.

- The conductors will be freed from the insulation that falls pulverized with the piece of sheath into the collection tray below

Application Range from 0.5mm up to 6mm of cable diameter.

Fast processing in about 1÷5 seconds.

Equipment in conformity with CE safety rules.

Power supply: 230V single phase 50/60Hz, 100Wp

Dimensions: (LxWxH) 500x200x200 mm 20Kg

Made with robust materials to withstand heavy duty production.

It's available an additional Safety Foot-switch command lever.

Spare seal protection for dust on the vibrating piston.

Felisari & C. s.r.l.

Felisari & C. s.r.l.